A construction management plan defines how a project will be organized, scheduled and executed from preconstruction through closeout. It ties together objectives, stakeholders roles and deliverables to create a unified approach for delivering the project safely on time and on budget. Use this guide to build a construction management plan that clarifies responsibilities, manages risk and keeps communication channels open across teams and contractors.

This guide provides practical steps, templates and examples to help you draft a construction management plan tailored to your project size and complexity. It covers the core elements you must include, explains how to sequence planning tasks and shows how modern tools can make the plan easier to maintain and monitor as the project moves forward. Whether you are leading a small renovation or a large commercial build, this resource will help you produce a plan that is actionable and defensible.

Get your free

Construction Management Plan Template

Use this free Construction Management Plan Template for Word to manage your projects better.

What Is a Construction Management Plan?

A construction management plan is a comprehensive document that establishes how a project will be delivered. It records the project objectives, stakeholder expectations, delivery milestones and governance structure. The document also lays out procurement strategies, communication protocols, site logistics safety requirements and quality control measures so everyone understands the rules of engagement for the work ahead.

Unlike a checklist, the construction management plan integrates scheduling, budgeting, resource allocation and risk management into one reference that guides decision making throughout the lifecycle. It becomes the primary source for progress monitoring, dispute resolution and regulatory compliance by documenting who does what by when and how success will be measured.

Construction project teams increasingly use construction project management software for planning, managing and tracing these plans because the software centralizes documents, tracks changes and provides live visibility into schedules, budgets and resources. Software reduces manual update work and prevents version control errors by storing the construction management plan alongside task lists, Gantt charts and communication threads. Teams gain audit trails for approvals and easier reporting for stakeholders which simplifies governance.

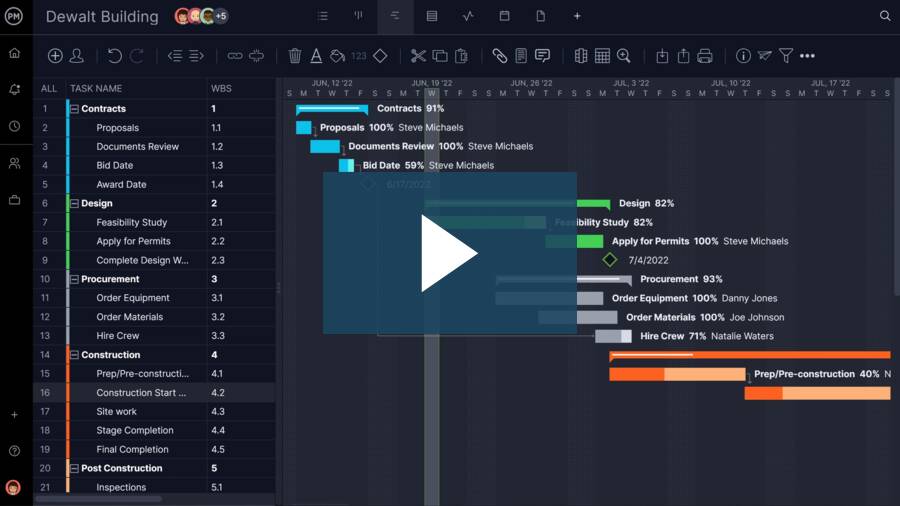

ProjectManager stands out as construction project management software because it combines industry-standard scheduling with intuitive collaboration and powerful reporting tailored to complex builds. Our Gantt charts are interactive, link all four types of task dependencies and automatically filter for the critical paths. Resource management features make it easier to coordinate subcontractors and balance labor across sites. Real-time dashboards and customizable reports remove manual status updates while secure timesheets capture labor costs for accurate job costing. Get started with ProjectManager today for free.

What Is Construction Management Planning?

Construction management planning is the process of preparing the documents, decisions and systems that will guide a project from kickoff to completion. It involves translating project objectives into executable programs by defining scope, schedules, budgets, resource needs and quality expectations. Good planning anticipates constraints and creates contingency measures so the project team can respond to inevitable changes on site.

This planning phase engages stakeholders to align expectations, assigns ownership for major deliverables and establishes the governance needed to manage performance. It is iterative by nature so the construction management plan should be reviewed and updated as design clarifications, procurement outcomes or site discoveries require. Treat the plan as a living document that supports transparency and informed decision-making across the construction team.

Watch this short video to learn how our software supports construction project management.

What Should Be Included in a Construction Management Plan?

A clear construction management plan covers both high-level strategy and detailed operational elements. The list below identifies essential sections and explains the purpose of each item so you can assemble a complete plan that anticipates common project challenges while meeting regulatory and contractual obligations.

- Project Overview: The project overview summarizes the development, including location, primary objectives, major deliverables and key stakeholders. It gives a concise statement of intent that orients readers to the overall purpose, timeline and expected outcomes. Include the owner, developer, main contractor and the project duration so the construction management plan starts with clear context and accountability.

- Scope of Work: The scope of work details the task inclusions and exclusions for the project, including boundaries and interfaces with existing structures. It clarifies which trades are responsible for which elements and describes performance expectations and deliverables. This prevents scope creep by providing yardsticks for change requests and acceptance criteria within the construction management plan.

- Resource Requirements: Resource requirements list labor categories, equipment, materials and specialist services needed to complete the work. It identifies quantities, timing and any long lead items that require early procurement. Including resource assumptions and contingency buffers ensures the construction management plan supports realistic scheduling and avoids costly last-minute substitutions.

- Construction Schedule: The construction schedule sets major milestones, the sequence of work and the critical path logic. It shows procurement windows, phased activities and key inspections. A well-defined schedule in the construction management plan helps coordinate subcontractors and reduces downtime by aligning deliveries with on-site needs.

- Construction Budget: The construction budget breaks down estimated costs by work package, including direct costs, indirect costs, contingencies and allowances. It establishes control thresholds and approval processes for budget changes. By tying budget line items to schedule and resources, the construction management plan supports proactive cost control and forecasting.

- Architectural Drawings: Architectural drawings provide the visual definition of design intent, including floor plans, elevations, sections and general notes. The construction management plan references the baseline drawing set and documents revision control procedures, so teams know which drawings are for construction and which are for information only.

- CAD Documents and Renderings: CAD documents and renderings include detailed digital models and visualizations used for coordination clash detection and client approvals. They support accurate takeoffs and sequencing decisions. The construction management plan should specify file formats, naming conventions and responsibility for model updates to maintain consistency.

- Construction Specifications: Construction specifications define material standards, installation methods, testing criteria and acceptance requirements. They complement drawings by describing performance requirements and testing protocols. Including specifications in the construction management plan reduces ambiguity and provides objective measures for quality assurance and inspections.

- Construction Procurement Plan: The procurement plan outlines sourcing strategies, vendor selection timelines, contract types and delivery logistics. It flags long lead items and critical suppliers that could impact the schedule. By aligning procurement milestones with the construction management plan, you reduce the risk of late deliveries that stall on site progress.

- Construction Safety Plan: The safety plan documents site-specific hazard assessments, emergency response procedures, permit to work systems and worker training requirements. It assigns safety responsibilities and sets inspection and reporting routines. Integrating safety into the construction management plan ensures compliance with regulations while protecting workers and minimizing downtime from incidents.

- Construction Traffic Plan: The traffic plan manages site access, egress routes, deliveries and pedestrian safety around the work zone. It coordinates with local authorities for permits and road closures where needed. Including traffic controls in the construction management plan reduces risks to the public and helps maintain steady supply chains to the site.

- Construction Waste Management Plan: The waste management plan defines handling, segregation, recycling and disposal procedures for demolition and construction waste. It identifies storage locations and responsible parties for waste removal. Documenting these controls in the construction management plan supports environmental compliance and can reduce disposal costs through recycling strategies.

- Change Management Plan: The change management plan outlines how scope changes will be requested, reviewed, estimated and approved, including impact assessment and documentation requirements. It sets authority levels for approvals and timelines for pricing and implementation. A robust change management process in the construction management plan prevents disputes and keeps the project on track.

- Risk Management Plan: The risk plan identifies potential threats and opportunities, assigns ownership and defines mitigation and response strategies. It includes probability and impact assessments and contingency reserves. Embedding a risk register in the construction management plan enables proactive monitoring and quick escalation when issues emerge on site.

Construction Management Plan Template

Download this free construction management template for Word to plan, execute and track their projects. It organizes essential details into clear sections such as project overview, scope of work, resource requirements and budget. By using simple Word-friendly tables, this template makes it easy to document milestones, responsibilities and safety protocols in a format that anyone on the team can access and understand. It removes ambiguity by standardizing how project information is captured, helping stakeholders stay aligned on objectives, schedules and deliverables.

The template is especially valuable for smaller teams or organizations that need a straightforward planning tool without the complexity of dedicated software. With predefined sections for procurement, safety, waste management and risk, it ensures no critical detail is overlooked during planning or execution. Project managers can customize the template to fit specific jobs while maintaining consistency across projects. A free construction management template for Word not only saves time in setup but also improves communication, accountability and compliance, creating a reliable foundation for successful project delivery.

Steps to Make a Construction Management Plan

Creating a construction management plan involves structured steps from stakeholder engagement through permitting and mobilization. The sections below break the process into ten practical phases with guidance on what to include and why each step matters for a robust construction management plan.

1. Gather Requirements from Project Stakeholders

Start by interviewing the owner, architect, engineers, end users and major subcontractors to collect requirements and expectations. Capture project objectives, success criteria, constraints and any regulatory or community needs that could affect delivery. Document functional requirements and acceptance criteria so the construction management plan reflects stakeholder priorities. Early alignment reduces rework and expedites approvals during construction.

Related: Free Requirements Gathering Template

2. Conduct a Feasibility Study

Assess technical, economic and regulatory feasibility, including site constraints, utilities access and environmental considerations. Analyze alternative delivery methods and high-level cost and schedule estimates to determine whether the project should proceed as proposed. Document assumptions, risks and recommendations so the construction management plan includes realistic baselines for budgeting and scheduling decisions.

Related: Free Feasibility Study Template

3. Analyze the Construction Job Site

Perform a detailed site assessment to identify access points, staging areas, soil conditions and existing utilities. Evaluate site topography, drainage and environmental restrictions that will influence sequencing and logistics. Mapping these findings in the construction management plan informs the location of temporary facilities, traffic routing and material handling strategies to minimize disruption during construction.

4. Create a Work Breakdown Structure

Develop a hierarchical work breakdown structure that decomposes the project into manageable work packages aligned with trades and procurement bundles. Each work package should have deliverables, schedules, cost estimates and assigned owners. Using the WBS in the construction management plan improves estimating, scheduling and risk assignment while enabling clearer accountability through construction execution.

Related: Free Work Breakdown Structure Template

5. Do a Material Takeoff and Quantity Takeoff

Produce detailed takeoffs from drawings and models to quantify materials required for each work package. Validate quantities with suppliers and consider waste factors and allowable tolerances. Accurate takeoffs feed procurement schedules and cost estimates so the construction management plan can align deliveries with installation windows and reduce double handling or material shortages.

6. Create a Bill of Quantities

Compile the quantity takeoffs into a formal bill of quantities that supports tendering and subcontractor pricing. The bill should be organized by work package and include unit rates, extensions and allowances for provisional items. Including a clear bill of quantities in the construction management plan helps ensure bids are comparable and supports transparent contract administration.

7. Estimate Project Costs

Prepare a detailed cost estimate that includes direct costs, indirect costs, contingencies and escalation assumptions. Base estimates on the bill of quantities, historical productivity rates and supplier quotes. Document cost breakouts by phase and work package so the construction management plan provides an auditable financial baseline for cash flow forecasting and change order evaluation.

Related: Free Job Estimate Template

8. Hire a General Contractor or Subcontractors

Choose procurement strategies that match project complexity and owner preferences, whether that is design-bid-build, design-build or construction management at risk. Prequalified bidders evaluate capacity, safety record and bonding ability. Once selected, negotiate clear scopes, commercial terms and performance milestones so the construction management plan sets expectations for delivery and dispute resolution.

9. Prepare the Job Site Facilities

Plan site offices, welfare facilities, parking and temporary utilities before mobilization. Identify secure material storage areas, laydown zones and equipment access routes. Establish site security and environmental protections for sensitive areas. Documenting site setup in the construction management plan expedites mobilization and creates a safer more efficient working environment from day one.

10. Obtain Permits

Identify required permits, approvals and inspections from local authorities, agencies and utility providers early in the schedule. Prepare submission packages with drawings, specifications and supporting reports and budget adequate time for reviews. Recording permit responsibilities, timelines and conditions in the construction management plan prevents regulatory delays and ensures compliance throughout construction.

Who Makes the Construction Management Plan?

The construction management plan is typically developed by the project management team in collaboration with the owner design team and lead contractors. Key contributors include the project manager who coordinates inputs, the construction manager who defines site logistics and the design leads who supply drawings, specifications and technical clarifications. Procurement and safety specialists provide input on contracting strategies and hazard controls.

Smaller projects may assign development of the construction management plan to the general contractor with approvals from the owner and design team. On larger projects, a dedicated planning team compiles the plan and maintains updates as the project progresses. Regardless of structure, the critical factor is multi-stakeholder involvement so the construction management plan reflects operational realities and regulatory requirements from the outset.

Implement governance for reviewing and approving the construction management plan by defining signatories, change control thresholds and update cadences. Assign a single document owner responsible for version control and distribution so the plan remains the authoritative reference for project delivery. This avoids confusion and ensures the construction management plan directs work consistently across teams and contractors.

Construction Management Plan Example

Below is a sample outline of what a filled construction management plan might look like in practice. Each section provides an applied perspective to demonstrate how the concepts work together to guide an actual project from early preparation through execution and closeout.

Project Overview

The Midtown Office Tower project involves constructing a 15-story commercial building with retail space on the first floor and Class A offices above. Located in the downtown district, the project will deliver 200,000 square feet of leasable space within 30 months. Key stakeholders include the property developer, general contractor, city planning office and anchor tenants.

Scope of Work

The scope includes demolition of existing structures, excavation, deep foundation installation, superstructure framing, curtain wall installation, mechanical and electrical systems, interior finishes and site landscaping. Exclusions are tenant-specific fit-outs and furniture procurement, which will be managed under separate contracts.

| Phase | Major Activities | Responsible Trade | Deliverables | Exclusions |

| Site Preparation | Demolition, grading, utilities relocation | Civil Contractor | Cleared and leveled site | None |

| Foundation & Structure | Deep piles, reinforced concrete core, steel framing | Structural Contractor | Load-bearing frame and slabs | Underground parking |

| Envelope | Curtain wall, roofing, insulation | Façade & Roofing Contractors | Completed weather-tight shell | Signage & branding |

| MEP Systems | HVAC, plumbing, fire protection, electrical | MEP Specialists | Operational systems | Smart sensors |

| Interior Fit-Out | Core areas, restrooms, elevators, lobbies | Finishing Contractor | Move-in ready core spaces | Tenant customization |

| Landscaping | Sidewalks, planters, lighting | Landscaping Co. | Completed outdoor area | Art installations |

Related: Free Construction Scope of Work Template

Resource Requirements:

The project requires approximately 150 skilled workers at peak, tower cranes, concrete pumping equipment and BIM coordination software.

| Resource Type | Description | Quantity | Timing | Responsible Party |

| Skilled Labor | Carpenters, electricians, HVAC technicians | ~150 at peak | Months 8 – 22 | Skyline Build Group |

| Heavy Equipment | Tower crane, concrete pump, boom lift | 5 units total | Months 3 – 18 | Site Equipment Rentals Inc. |

| Materials | Structural steel, glass panels, concrete mix | 2,000 tons steel, 12,000 m³ concrete |

Staggered | Horizon Procurement |

| Technology | BIM 360, Procore, drones for inspections | 3 licenses, 2 drones | Entire project | Project Controls Team |

| Subcontractors | Façade, plumbing, elevator installers | 8 firms | Per schedule | Procurement Dept. |

Specialized subcontractors will be engaged for façade installation, HVAC systems and fire protection. A dedicated safety officer and logistics manager will also be on-site full-time.

Construction Schedule

The timeline begins with site preparation in Q2, foundation completion in Q4 and structural topping out by Q2 of the following year.

| Milestone | Planned Start | Planned Finish | Duration | Responsible Party |

| Site Preparation | Jan 2025 | Apr 2025 | 4 months | Civil Contractor |

| Foundation Completion | May 2025 | Oct 2025 | 6 months | Structural Division |

| Structural Topping Out | Nov 2025 | Jun 2026 | 8 months | Steel Contractor |

| Envelope Completion | Jul 2026 | Dec 2026 | 6 months | Façade Contractor |

| Interior & MEP Fit-Out | Jan 2027 | Apr 2027 | 4 months | MEP & Interiors Team |

| Testing & Commissioning | May 2027 | Jun 2027 | 2 months | QA/QC Team |

Curtain wall and MEP rough-ins follow, with interior finishes concluding in the final two quarters. Commissioning and inspections are planned for the last 60 days before turnover.

Construction Budget

The total budget is $150 million, broken down into $100 million for direct construction costs, $20 million for design and engineering, $15 million in contingencies and $15 million for permits, fees and financing. Monthly cost reports will track actual spend against forecast.

| Cost Category | Description | Estimated Cost (USD) | % of Total | Cost Owner |

| Structural Works | Concrete, steel, rebar, formwork | $45,000,000 | 30% | Structural Manager |

| MEP Systems | HVAC, electrical, plumbing, fire protection | $25,000,000 | 17% | MEP Coordinator |

| Architectural Finishes | Interior, glazing, façade, roofing | $20,000,000 | 13% | Finishes Lead |

| Site & Civil Works | Earthworks, utilities, paving | $10,000,000 | 7% | Civil Engineer |

| Design & Engineering | Consultants, permits, approvals | $15,000,000 | 10% | Project Controls |

| Contingency | Risk reserve & escalation | $10,000,000 | 7% | Finance |

| Indirect Costs | Temporary facilities, insurance, admin | $15,000,000 | 10% | Project Management |

| Total Budget | $150,000,000 | 100% |

Related: Free Construction Budget Template

Architectural Drawings

The design package includes baseline construction drawings approved by city authorities, covering site plans, elevations, sections and detailed floor layouts. Revisions will be tracked through a document control system to ensure only the current issue is used in the field.

| Drawing Set | Sheet Range | Description | Revision Date | Approved By | Distribution |

| A100–A199 | Site & Floor Plans | Layout of all floors, utilities, landscape plan | Feb 2025 | Vega Design Studio | Construction Team, City Planning |

| A200–A249 | Elevations & Sections | Façade elevations, roof sections, wall details | Mar 2025 | City Planning Authority | Structural & Façade Contractors |

| A300–A329 | Stair & Core Details | Vertical circulation, shaft dimensions, fireproofing | Apr 2025 | Fire Marshal’s Office | MEP & Safety Teams |

| A400–A499 | Interior & Finishes | Lobby, restrooms, elevator lobbies, ceiling plans | Jun 2026 | Owner Representative | Interiors Team |

| A500–A550 | Landscape & Exterior Works | Hardscape, lighting, planter details | Jan 2027 | Horizon Urban Partners | Landscaping Subcontractor |

CAD Documents and Renderings

A coordinated BIM model provides 3D visualization, clash detection and integrated schedules. Renderings are used for stakeholder presentations and tenant marketing. File sharing is managed through a cloud platform with controlled access for consultants and subcontractors.

| File Name | Type | Purpose | Format | Owner | Platform |

| MidtownTower_Model_v12 | BIM Model | Coordination of structure, MEP & architecture | .rvt | BIM Coordinator | Autodesk Construction Cloud |

| MidtownTower_Render_Lobby | 3D Rendering | Client presentation & marketing materials | .jpg / .mp4 | Vega Design Studio | Marketing Folder |

| MidtownTower_MEP_Overlay | Clash Detection | Detect pipe & duct conflicts | .nwc | MEP Engineer | BIM 360 |

| MidtownTower_Structure_Export | Structural Detailing | Fabrication reference for rebar & steel | .dwg | Structural Engineer | Procore |

| MidtownTower_Roof_Terrace | Visualization | Rooftop garden concept for tenants | .fbx | Architect | Marketing Drive |

Construction Specifications

Specifications call for a reinforced concrete structure, a unitized curtain wall system, high-efficiency HVAC and low-flow plumbing fixtures. Quality standards reference ASTM and ISO benchmarks, with third-party testing required for structural materials and mechanical systems before acceptance.

| Division | Specification Type | Material/Standard | Testing Method | Responsible Party | Notes |

| Division 03 | Concrete Works | ASTM C150 Type I Portland Cement | Slump & compressive strength tests | Structural Engineer | 28-day strength: 5,000 psi |

| Division 08 | Openings (Windows/Doors) | Aluminum frame curtain wall, Low-E glass | Air/water infiltration tests | Façade Specialist | Meets ASHRAE 90.1 |

| Division 09 | Finishes | Acoustic ceiling panels, ceramic tiles | Field adhesion test | Interiors Contractor | Fire-rated materials |

| Division 15 | Mechanical Systems | Variable air volume HVAC with BMS | Pressure test & commissioning | MEP Engineer | ERV system included |

| Division 26 | Electrical Systems | 480V/277V, LED lighting, smart sensors | Load balance & grounding test | Electrical Subcontractor | Meets NEC 2023 |

Construction Procurement Plan

Long-lead items such as curtain wall panels and custom air-handling units are ordered 12 months in advance. A mix of lump sum and guaranteed maximum price contracts are used to balance cost certainty with flexibility. Procurement milestones align with the critical path in the master schedule.

| Procurement Item | Description | Contract Type | Lead Time | Vendor | Order Date | Delivery Date |

| Curtain Wall Panels | Custom aluminum and glass façade | Lump Sum | 8 months | Skyline Façades Ltd. | Oct 2025 | Jun 2026 |

| Air Handling Units | High-efficiency modular units | GMP | 9 months | ThermoTech Systems | Sep 2025 | May 2026 |

| Elevators | 6 high-speed traction lifts | Fixed Price | 7 months | ElevatePro Inc. | Oct 2025 | May 2026 |

| Concrete Supply | Ready-mix for structure and foundations | Unit Rate | 1 month | MetroMix Concrete | Feb 2025 | Ongoing |

| Interior Finishes | Marble, ceiling tiles, fixtures | Lump Sum | 3 months | Urban Interiors Co. | Nov 2026 | Feb 2027 |

Related: Free Procurement Plan Template

Construction Safety Plan

Daily toolbox talks, weekly inspections and monthly audits form the backbone of the safety program. A zero-tolerance policy applies to fall hazards and PPE violations. Emergency response drills are conducted quarterly, and incident reports are logged electronically with corrective action follow-up.

| Safety Activity | Frequency | Responsible Party | Documentation | KPI / Target | Remarks |

| Toolbox Talks | Daily before shift | Site Supervisors | Attendance Logs | 100% participation | Topics vary weekly |

| Site Inspections | Weekly | Safety Officer | Inspection Reports | Zero critical findings | Escalate within 24 hrs |

| Safety Training | Monthly | HR & Safety Dept. | Certificates of Completion | All new hires trained | Includes fall protection |

| Emergency Drills | Quarterly | Safety Officer | Drill Reports | Evacuation under 3 min | Coordinate with Fire Dept. |

| Incident Reporting | As needed | Site Managers | Digital Forms in Procore | Corrective actions <48 hrs | All incidents logged |

Construction Traffic Plan

A designated entry point on the north side manages heavy truck deliveries with flaggers directing flow. Deliveries are scheduled during off-peak hours to reduce disruption to city traffic. Pedestrian walkways are protected with covered scaffolding along the main street frontage.

| Route / Access Point | Purpose | Vehicle Type | Operating Hours | Control Measures | Responsible Party |

| North Gate (Main Access) | Entry for deliveries and heavy equipment | Concrete trucks, cranes | 6:00 AM – 3:00 PM | Flaggers and signal lights | Site Logistics Manager |

| East Alley | Exit route for dump trucks and waste haulers | Dump trucks | 7:00 AM – 4:00 PM | One-way signage, spotters | Waste Subcontractor |

| Main Street Frontage | Pedestrian protection and small deliveries | Delivery vans | 9:00 AM – 12:00 PM | Covered scaffolding, fencing | Site Safety Officer |

| South Access (Temporary) | Utility and electrical installations | Service vehicles | 8:00 AM – 5:00 PM | Traffic cones, escort required | Electrical Contractor |

| Coordination Zone | Temporary road closures for crane lifts | Mobile crane setup | As needed | City permits & police escort | Project Manager |

Construction Waste Management Plan

Concrete, steel and drywall waste are segregated on site and sent to recycling facilities, with a target of diverting 75 percent of waste from landfill. Hazardous materials such as adhesives and solvents are stored separately and disposed of under regulatory guidelines.

| Waste Type | Source Activity | Handling Method | Recycling / Disposal Facility | Target Diversion (%) | Frequency | Responsible Party |

| Concrete & Masonry | Demolition & structural work | Segregate & crush on site | Metro Recycling Facility | 85% | Weekly | Site Superintendent |

| Metals | Framing, rebar, ductwork | Sort by type, labeled bins | SteelCycle Depot | 90% | Weekly | Logistics Coordinator |

| Wood & Packaging | Pallets, crates, temporary forms | Separate clean vs. treated | GreenCity Waste Transfer | 70% | Twice weekly | Waste Contractor |

| Drywall & Plaster | Interior buildout | Store dry, recycle offsite | BuildSmart Recycling | 75% | Weekly | Finishes Supervisor |

| Hazardous Waste | Adhesives, solvents, aerosols | Secure containers & manifest | EcoSafe Hazard Disposal | 100% | Monthly | Safety Officer |

Change Management Plan

All change requests must be submitted in writing with cost and schedule impact assessments. The project manager reviews each request and escalates it to the steering committee for approval if it exceeds preset thresholds. Approved changes are incorporated into the schedule and budget at monthly update cycles.

| Change ID | Description | Originator | Impact (Cost/Schedule) | Approval Level | Status | Date |

| CHG-001 | Upgrade lobby flooring from ceramic to marble | Owner | +$120,000 / +5 days | Steering Committee | Approved | Mar 2026 |

| CHG-002 | Relocate rooftop HVAC units for better access | MEP Engineer | +$35,000 / +2 days | Project Manager | Approved | Sep 2026 |

| CHG-003 | Add EV charging stations in parking area | Developer | +$80,000 / +3 days | Steering Committee | Under Review | — |

| CHG-004 | Substitute façade glass for higher acoustic rating | Architect | +$60,000 / none | Owner | Approved | Oct 2026 |

| CHG-005 | Modify lighting layout in retail spaces | Tenant | +$15,000 / +1 day | Project Manager | Pending | — |

Related: Free Change Management Plan Template

Risk Management Plan

Key risks identified include weather delays, labor shortages and supply chain disruptions for curtain wall components. Mitigation strategies involve securing backup suppliers, scheduling weather-sensitive activities in drier months and maintaining a labor pool agreement with local unions.

| Risk ID | Risk Description | Probability | Impact | Mitigation Strategy | Owner | Status |

| R-01 | Delay in curtain wall delivery | Medium | High | Prequalify secondary supplier; include schedule buffer | Procurement Manager | Open |

| R-02 | Labor shortage during peak period | High | High | Partner with local unions; maintain standby labor pool | Construction Manager | Monitoring |

| R-03 | Severe weather affecting concrete pours | Medium | Medium | Use insulated formwork; adjust pour schedule by forecast | Site Superintendent | Mitigated |

| R-04 | Safety incident involving height work | Low | High | Enforce PPE; daily toolbox talks | Safety Officer | Ongoing |

| R-05 | Material cost escalation | Medium | High | Lock supplier prices early; maintain 7% contingency fund | Project Controls Lead | Open |

A risk register is updated biweekly with input from trade contractors.

Free Related Construction Management Planning Templates

In addition to a full construction management plan, individual templates can help project teams focus on specific aspects of planning. These free resources simplify budgeting, scheduling and scope definition so managers can save time while ensuring accuracy. Each template is designed to address a core component of construction planning and can be used on its own or alongside a full management plan.

Construction Budget Template

Download this free template to organize estimated and actual costs into categories such as labor, materials, equipment and contingencies. It provides a straightforward way to monitor project spending against approved budgets and helps prevent overruns. Using a construction budget template also supports transparency and makes reporting easier for stakeholders.

Construction Schedule Template

Use this free construction schedule template to outline tasks, milestones and dependencies in a clear timeline. It helps managers allocate resources efficiently and identify potential delays before they impact delivery. By mapping out activities from start to finish, this template ensures that teams work in sequence and deadlines are met.

Construction Scope of Work Template

This free scope of work template defines project inclusions and exclusions, roles and deliverables. It establishes boundaries and expectations that reduce misunderstandings and disputes during execution. A construction scope of work template also supports accountability by clarifying what each party is responsible for from the outset.

ProjectManager Is Ideal for Making a Construction Management Plan

Templates are fine, but limited tools. To get a better handle on planning, executing and tracking, professionals use construction project management software. ProjectManager offers multiple project views that fit the needs of different stakeholders. Project managers can oversee complex timelines with interactive Gantt charts, while subcontractors may prefer to work from kanban boards or task lists that simplify daily assignments. Calendar views make it easy to coordinate inspections and site activities, ensuring every participant has the flexibility to work in the format that best suits their responsibilities while still staying connected to the same live project data.

Balance Workloads With Resource Management

ProjectManager’s resource management tools give construction managers a real-time picture of team and equipment capacity. The workload chart uses color coding to quickly show when crews or subcontractors are overbooked, making it simple to reassign tasks and balance demand.

On the team page, managers can view all active assignments, shift schedules or redistribute work across multiple projects. This level of visibility helps prevent delays caused by overstretched crews and supports efficient use of costly resources like cranes or specialty trades.

Track Progress and Costs with Mobile-Ready Tools

Tracking is streamlined through live dashboards, customizable reports and secure timesheets that can be updated directly from the job site with our mobile app. Crews log hours from the field, giving managers immediate insight into labor costs and productivity without waiting for paper records.

Dashboards update in real time to show progress against milestones and budget forecasts, while reports can be tailored for clients or internal stakeholders. By combining mobile timesheets with automated reporting, our software ensures accurate job costing, compliance with labor requirements and transparent communication across the entire construction team.

Related Construction Management Planning Content

There’s more to managing a construction project than making a construction management plan. For readers interested in learning more, check out the links below. They define different types of construction projects, methods and techniques, among other things.

- 10 Types of Construction Projects with Examples

- 18 Construction Methods and Techniques

- Construction Contingency: A Quick Guide

- Critical Path Method (CPM) in Construction: A Quick Guide

- 8 Free Construction Forms for Excel and Word

- 14 Types of Construction Contracts: Pros, Cons & Best Practices

ProjectManager is online project and portfolio management software that connects teams, whether they’re in the office or on the job site. They can share files, comment at the task level and stay updated with email and in-app notifications. Get started with ProjectManager today for free.