On a construction site, plans are constantly tested by weather, labor availability, inspections and late deliveries. To stay in control of near-term work, teams rely on a lookahead schedule to focus attention on what must happen next, not what was planned months ago in the master construction schedule.

What Is a Lookahead Schedule In Construction?

A lookahead schedule in construction is a short-term planning view, or in other words a zoomed-in version of a fragment of the master construction schedule, that breaks upcoming work into detailed, near-future activities. It translates higher-level schedule logic into a schedule for specific tasks crews can easily understand, prepare for and execute.

Unlike master schedules, lookahead schedules typically cover a two, three or six week window and focus on immediate construction task sequencing, constraints and readiness rather than long-term milestones or contractual completion dates. They sit between the overall construction schedule and daily work planning processes used across most active construction sites.

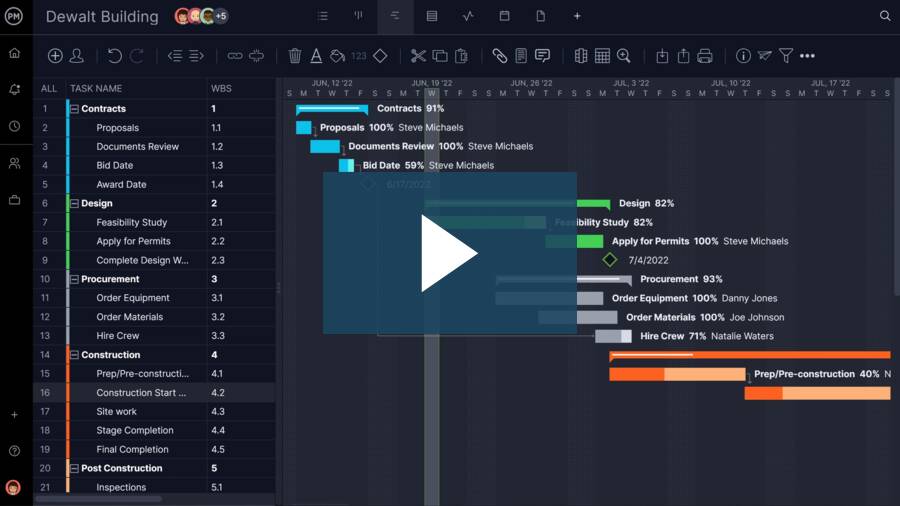

ProjectManager is an award-winning construction scheduling software designed for making detailed master construction schedules and lookahead schedules thanks to its powerful project planning, scheduling and monitoring features. With ProjectManager’s Gantt chart you can visualize task dependencies, identify critical path activities, allocate resources, track costs and compare estimates vs. actual project performance. Get started today for free.

What Is the Purpose of a Lookahead Schedule In Construction?

The purpose of a lookahead schedule in construction is to make near-term work clear, predictable and workable for field teams. It is used when upcoming tasks need clarification, coordination or confirmation before crews mobilize.

Lookahead schedules are especially necessary when trades overlap, materials have lead times, access is limited or unresolved constraints could disrupt planned work in the coming weeks. They help project teams decide what must be ready before work can realistically proceed without last-minute rework or delays on site.

These are the most common scenarios in which lookahead schedules are used in construction projects

- When upcoming work depends on inspections, permits or approvals that must clear before crews can mobilize.

- As trades begin to overlap and sequencing needs to be tightened to avoid crews working over or around each other.

- When material deliveries have long lead times and exact installation dates must be confirmed weeks in advance.

- After changes to scope, design or means and methods force short-term replanning without rewriting the entire master schedule.

- During periods of schedule instability, such as weather disruptions, labor shortages or recovery from prior delays.

Benefits of Using a Lookahead Schedule In Construction

By breaking a large construction schedule into near-term detail, a lookahead schedule makes upcoming work easier to understand for superintendents, foremen, trade leads, project engineers and subcontractor coordinators.

Instead of interpreting abstract milestones, these roles see concrete tasks, readiness needs and timing, which improves daily coordination, short-term decision-making and communication across the site during planning meetings and weekly field huddles.

- Clarifies what work is actually ready to start by surfacing missing materials, approvals or access constraints before crews arrive, reducing false starts, idle time and last-minute rescheduling on active construction sites.

- Improves coordination between trades by showing short-term sequencing clearly, helping superintendents resolve handoff conflicts, adjust crew stacking and confirm who works where and when during upcoming construction phases, on site.

- Supports more reliable weekly commitments by aligning planned tasks with real constraints, so foremen promise only work that can be completed as scheduled without surprises, rework, delays or trust erosion.

- Creates an early warning signal for schedule risk by exposing upcoming bottlenecks weeks ahead, giving project teams time to intervene before delays impact milestones or contractual completion commitments on projects.

- Reduces reliance on reactive firefighting by shifting planning conversations earlier, allowing decisions to be made calmly instead of under day-of pressure from crews, managers, subcontractors and inspectors across the site.

- Improves communication between field and office teams by translating master schedule intent into language crews can act on immediately during daily planning, coordination meetings, briefings, walkthroughs, updates and reviews onsite.

- Helps maintain momentum during disruptions by recalibrating near-term priorities quickly, keeping crews productive even when original plans change due to weather, inspections, supply delays, scope changes or site conditions shifting.

How to Make a Lookahead Schedule

Now that we have a better understanding of the use of lookahead schedules in construction projects, let’s go through some key steps to make one.

1. Start From the Master Schedule

Begin by anchoring the lookahead schedule to the approved construction schedule, which remains the authoritative plan for the project. The lookahead does not override the schedule baseline for the project, milestones or contractual dates. It simply narrows focus to the immediate stretch of work, translating the long term objectives of the project into near-term actions while respecting the task sequencing, dependencies and commitments already established at the project level.

2. Define the Lookahead Window

Select a lookahead window that reflects how far ahead the team can realistically plan with confidence. Most construction projects use a two-, three- or six-week horizon, depending on trade density, procurement lead times and site complexity. Shorter windows suit fast-moving interiors, while longer ones help with coordination-heavy phases where approvals, inspections or material readiness require earlier visibility.

3. Pull Relevant Upcoming Activities

From the master schedule, extract only the activities that fall within the selected lookahead window. Avoid carrying unnecessary long-term tasks into this view. If scheduled activities are too broad to manage effectively, break them into smaller, executable work packages that reflect how crews will actually perform the work in the field over the coming weeks.

4. Check Constraints and Readiness

Review each lookahead activity to confirm it is truly ready to be executed. This means verifying that materials are delivered or ordered, labor and equipment are available, permits and inspections are secured, and predecessor work is complete. Any missing prerequisite should be flagged immediately so it can be resolved before crews are scheduled and productivity is impacted.

5. Adjust Task Logic and Sequencing

Use the lookahead to refine how work will unfold in real site conditions. Update durations based on current productivity, resequence tasks where access or space is constrained, and align work with how crews actually move through the site. This step turns theoretical schedule logic into a practical plan that reflects weather, manpower and field realities.

6. Coordinate With Trades and Supervisors

Review the lookahead schedule collaboratively with subcontractors, foremen and field supervisors. This conversation is where assumptions are tested, handoffs are clarified and conflicts are resolved. By confirming what each trade can realistically commit to, the lookahead becomes a shared plan rather than a top-down directive disconnected from on-site execution.

7. Assign Short-Term Responsibilities

For every activity in the lookahead window, clearly identify who is responsible for executing and coordinating the work. Assigning ownership at this level strengthens accountability and helps supervisors manage daily priorities. When responsibilities are explicit, follow-ups are clearer and coordination issues are addressed faster as work progresses.

8. Update Weekly and Roll Forward

A lookahead schedule must evolve as the project moves forward. Update it weekly by removing completed tasks, adding newly upcoming activities and reassessing constraints. This rolling process keeps the schedule relevant and ensures planning stays proactive, allowing teams to respond to changes without losing control of near-term execution.

Free Construction Scheduling Templates

Our library includes a wide range of free construction project management templates built for Excel, Word, Google Sheets and other formats. The following templates are especially useful for construction scheduling.

Gantt Chart Template

This Gantt chart template for Excel makes it easy to create a visual project schedule. You just enter your tasks along with their start dates, end dates and durations, and the chart is generated automatically, saving time and avoiding manual formatting.

Construction Schedule Template

This construction schedule template lets you experience ProjectManager’s online Gantt chart in a real construction scenario. It helps you build a detailed task list, define dependencies, identify the critical path and organize scheduling logic the same way teams do when managing live construction projects.

Construction Scope of Work Template

This scope of work template provides a clear way to document what work is included in the project. By defining tasks, deliverables and responsibilities upfront, it helps keep the schedule aligned with the agreed scope and reduces confusion as work progresses.

ProjectManager Is Ideal for Construction Scheduling

ProjectManager is an award-winning construction project management software equipped with powerful planning, scheduling and tracking features that allow to create detailed construction schedules, establish baselines, identify project risks and compare estimated project timelines and costs against actual project performance to quickly identify delays and cost overruns. Watch the video below to learn more!

Related Construction Scheduling Content

Our content library features over 100 construction blogs, templates, ebooks and other types of content to help construction project managers better understand the many moving parts that must be managed to deliver successful construction projects. Here are some of them.

- Construction Milestones: Milestone Schedule Example

- 20 Best Construction Scheduling Software for 2026 (Free & Paid)

- Schedule Risk Analysis In Construction (SRA)

- Construction Sequencing: Making a Construction Sequence Plan

- Schedule of Values in Construction (Example & Template Included)

- Construction Resource Scheduling: Making a Resource Schedule

- How to Make a Material Schedule for Construction